Porto de Sergipe Combined-cycle Power Plant, Brazil

Location: Sergipe, Brazil

Owner/Operator: Centrais Elétricas de Sergipe S.A. (CELSE)

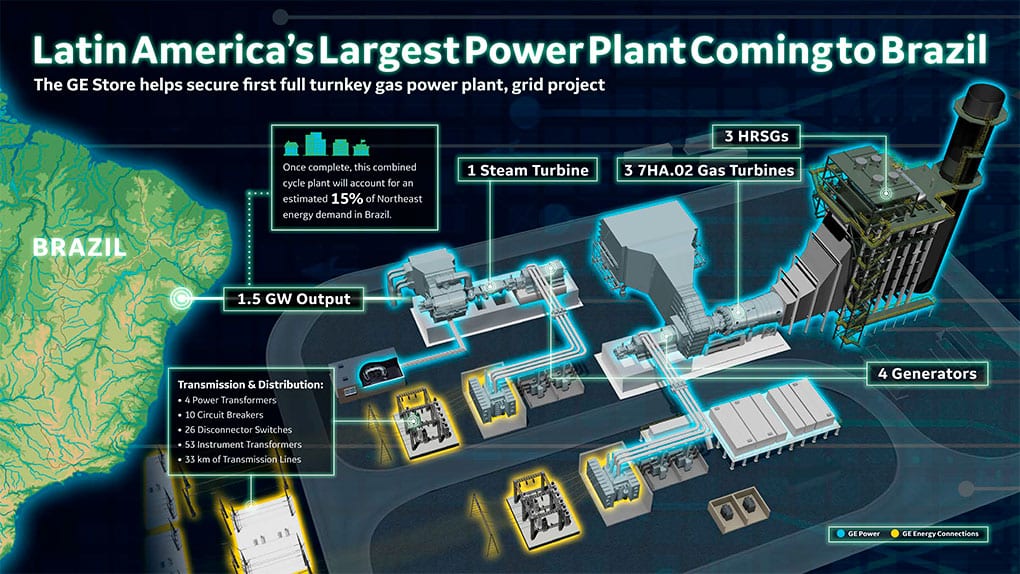

Brazil’s Porto de Sergipe combined-cycle power plant, now under construction, will be the largest and most efficient gas power plant in Latin America at start-up. The facility, when completed at a total Project cost of approximately $ 1.8 billion, will have a generating capacity of 1,516 MW and will be fueled by liquefied natural gas (LNG) supplied by Exxon Mobil Corp and delivered through a new floating off-shore natural gas storage and regasification terminal to be built as part of the project. The Complex, located near Aracaju, the state capital of Sergipe in North East Brazil, is scheduled to open by 2020

IFC (World Bank Group) and IIC (InterAmerican Development Bank) Environmental Noise Guidelines

As a condition of receiving financing from the International Finance Corporation (“IFC”) and the InterAmerican Investment Corporation (“IIC”), an environmental noise study was required. There are established residential areas close to the project site. The environmental noise limits of the IFC and IIC are more restrictive than those of the Brazilian National standard, applicable to the surrounding area.

Environmental Noise Assessment and Noise Control Recommendations

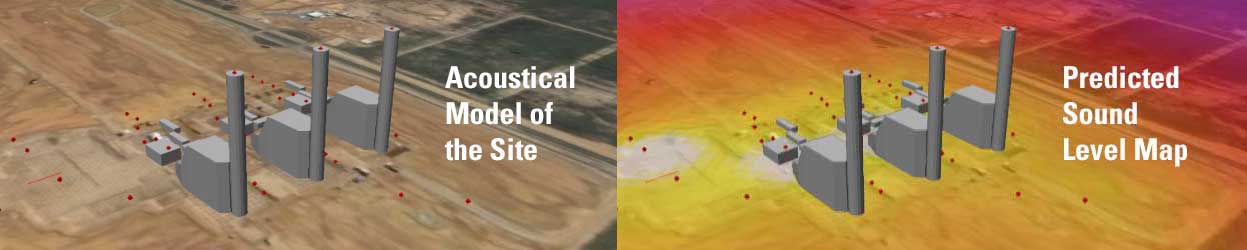

HGC Engineering was retained by CELSE to undertake a predictive noise impact and noise control study. Previous studies had demonstrated that the facility, as designed, would meet the Brazilian noise limits. However, additional detailed analysis was needed in order to assess the proposed plant relative to the more restrictive noise guidelines and noise limits of the IFC and IIC. HGC Engineering worked with the system supplier, G.E. Power, to obtain detailed sound emission data for each of the many components of the plant, including the three gas turbines, heat recovery steam generation systems, electrical generators, steam turbine, and ancillary equipment. That information, along with the topographical data for the site and surrounding area were used to create a three-dimensional, predictive computer model of the facility. HGC Engineering also assisted with monitoring by a local consultant of baseline “background” sound levels for a period of several days, as required by IFC/IIC guidelines, as the basis of assessment. Finally, HGC Engineering worked with G.E. Power and CELSE to identify additional noise control measures that could be incorporated in the design of the facility, in order to meet the IFC/IIC noise limits.

Acoustical engineering services delivered:

- Employed predictive analysis to determine the anticipated offsite sound levels in the neighboring residential communities, resulting from the future operations of the facility.

- Evaluated the anticipated sound levels with respect to the environmental nose assessment criteria of the World Bank, the InterAmerican Development Bank, and the Brazilian National standards.

- Identified whether noise control measures were likely to be needed, provided conceptual recommendations for such measures, as appropriate, and worked with the equipment supplier and client to incorporate those measures into the design of the facility