The Importance of Achieving Good Vibrations in Healthcare Facility Design

Traditional vibration control methods

The traditional preventative measure used to best alleviate vibration’s impact on sensitive equipment in an efficient and cost-effective manner has been to situate all operating rooms and diagnostic imaging systems on grade. This is because the innate stiffness, and mass of the soil directly below the grade base tends to act as a natural form of vibration mitigation. The inherent damping properties of soil can effectively reduce the amplitude of resonant vibration by converting a portion of the energy into low-grade heat.

New realities in hospital design create vibration mitigation challenges

New realities in hospital design create vibration mitigation challenges

Several new factors today have driven healthcare architects; structural engineers and planners to move beyond this tried and true, grade-level mitigation strategy. One new reality “on the ground” is that keeping diagnostic systems and operating rooms on grade is no longer a given or a viable option. Today modern space planning practices leans toward putting patient intake, lounges, food courts, loading docks, mechanical rooms and the like on valuable space at grade, squeezing out operating rooms and diagnostic imaging systems. Furthermore, high density urban planning, among other concerns, are forcing hospitals to build or expand vertically as multi-story high-rises, rather than horizontally across as in traditional low-rise healthcare facility design. The other impetus that has spurred change are recent advances in building systems and structural engineering that now allow diagnostic equipment and operating rooms to be relocated and their static loads supported by elevated slabs on higher floors. While innovative, state-of-the art structural engineering and reinforcements now allow for diagnostic systems and operating rooms to be situated above grade, lighter weight and increasingly flexible structural floor systems renders them more prone to vibration interference from sources throughout the building structure. What’s more, diagnostic and operating rooms imaging and surgical support technologies have become increasingly more sophisticated and sensitive relative to earlier generations of systems that operated at grade, making mitigation efforts more challenging today.

Shake, rattle or roll?

Steady State and Transient are the two basic categories of vibration that vibration consultants like HGC Engineering will consider when conducting an impact assessment in a healthcare setting. They will look at potential vibration sources in a building and its environs and broadly attempt to classify them into either of these two characteristic vibration dispositions. Steady State, as the name implies, is a continuous, regular source of vibration which typically originates from HVAC, mechanical and building systems, such as fans, pumps, cooling towers and chillers. Transient sources of vibration are those that are intermittent and produced from things such as pedestrian and cart traffic in corridors, emergency generators, elevator operations, loading dock activities, and helicopter landings. While some of these sources can exhibit both states at some point in their operations, a consultant will attempt to sort the equipment by their most dominant impact. Many sophisticated diagnostic equipment can tolerate higher transient vibration because they have built-in error-checking features that can detect faulty data results introduced by the occasional and irregular transient peaking and can perform “redos” or work-arounds to compensate. Nevertheless, in some scenarios, such as during ophthalmological procedures using surgical microscopes, diagnostic error checking has no value given the real-time nature of surgeries, where there is simply no room for errors and/or “redos”

Space planning and design

An initial component of a successful impact assessment procedure is to start by reviewing architectural drawings early on in the design process, identifying vibration sources which may be of concern with respect to structural vibration. This involves looking for operating, diagnostic or lab areas that may contain vibration-sensitive equipment, as well as structural areas that may be particularly prone to footfall or other event-induced vibration. Based on this review a catalog of vibration sensitive uses and internal processes or equipment that will generate vibration can be developed and equipment with the greatest potential for vibration sensitivity identified. A preliminary design guideline for vibration control can then be prepared for use by the design team during space planning. The guideline will provide information relevant for developing specifications for vibration isolation of mechanical equipment including appropriate isolator static deflections, and general guidance for avoiding bridging of isolation systems. The guideline can also provide general direction for avoiding potential issues caused by problem juxtapositions, such as high traffic corridors on elevated floors near or in the same structural bay as sensitive spaces. Another example of a questionable juxtaposition might be a ceiling-mounted surgical microscope that is found to be hanging from a lightweight structural floor for an area directly above it. Vibrations of this floor caused by human or mechanical activity in the above area may impact the surgical microscope in the operating room below. In this scenario an effective space planning solution would involve moving this operating room to another less impacted, more optimal bay location. Outdoor environmental related sources of vibration is another space planning consideration and would include, for example, looking at the location of major drive lanes in relation to MRIs. Something as seemingly innocuous as a speed bump or other discontinuities on a drive lane could lead to performance consequences on a nearby MRI. In this scenario, a simple planning consideration would be to restrict truck use in the drive lane, limiting their speed to a crawl when passage through the lane is unavoidable.

Vibration criteria and impact

With a catalogue of vibration sources now in hand, and input and feedback on proposed spaces and layouts given, a vibration specialist like HGC Engineering can review criteria standards for MRIs and CT scanners which are supplied by their manufacturers, such as GE or Siemens, who each have very different and fairly stringent specification criteria for their equipment because the vibration responses of each of their machine lines are variable and unique. In addition, each manufacturer has specific criteria peak levels for transient vibration as well as for steady state vibration as a function of frequency. However, early in the planning and design process, the exact brand of MRI or other sensitive equipment may not be known and therefore the criteria used for evaluation purposes at that stage must be derived from generic vibration classes, or allowable uses, as defined in several Canadian, American and International Guidelines and Standards that include:

- American/Canadian Institute of Steel Construction Design Guide 11

- The Steel Construction Institute (SCI P354) and The Concrete Centre (CCIP-016)

- American National Standard Institute (ANSI) Standard S3.29-1983, “Guide to the Evaluation of Human Exposure to Vibration in Buildings

- FGI (Facility Guidelines Institute’s) Guidelines Sound & Vibration Design Guidelines for Health Care Facilities (S&V-3.0-2014)

- The CSA Standard Z8000-11 (Canadian Health Care Facilities)

- ASHRAE 2011. Chapter 48, Noise and Vibration Control

- ISO 10137:2007 Bases for design of structures – Serviceability of buildings and walkways against vibrations

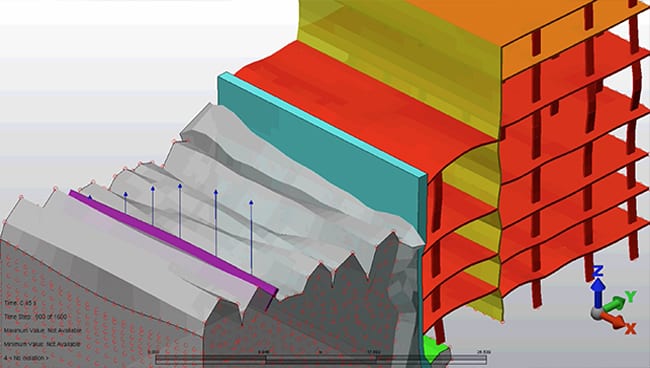

In an existing facility where a retrofit or expansion is occurring, measurements can be conducted to obtain ambient levels, and during simulated foot traffic. At the same time, measurements can be taken to determine the fundamental resonant frequency, damping, and mode shape of the vibration of representative bays which is useful in determining any necessary structural upgrades. The measurement results can then be analyzed against the established criteria to define the vibration class and typical allowable uses (operating rooms, general laboratory space, optical microscopes, etc.). Where areas with heightened potential for adverse vibration impacts are identified due to the preliminary structural design, it is prudent to undertake a dynamic finite element analysis of the building structure. Whereas mechanical systems can effectively be mitigated at its source, footfall-induced vibration typically needs to be addressed through the structural design, and required improvements can be identified with finite element analysis. An HGC Engineering vibration specialist can work with the design team to prepare specifications and details for the location and isolation of major mechanical systems. At the same time, they can also work with the structural engineer to ensure that recommendations to address specific areas of concerns are identified and remedied and to try and accommodate other considerations as they arise, which can affect potential stiffening or other remedial measures.

Mitigation strategies

In general there are some typical base strategies that can be implemented or considered in working to mitigate vibration impact on MRIs and other sensitive equipment. One strategy is to situate an MRI on a column line for added stiffness, with the closest corridors located near the perimeter of the bays. Installing an MRI on a concrete block that is two or three times thicker than the neighboring slab is another common way to further reduce the vibration from sporadic impacts. This block can serve to increase the inertia and can reduce the transfer of vibration to the block from bending waves in an adjoining slab. In the case of a ceiling-mounted surgical microscope, a mitigation solution may involve reinforcing the ceiling or isolating the microscope while also increasing its inertia with lead, steel or concrete.

Mitigation strategies during construction

Any new or future expansion construction activities near an existing MRI are also likely to be of concern if the system is situated against an exterior wall. Using a jackhammer or breaker on concrete within a bay or two is likely to produce vibration exceeding criteria. Generally speaking, pile driving outside an exterior wall will likely also exceed vibration criteria. Drilling for caissons will produce less vibration than pile driving, but could still be an issue depending on the soil. Similarly, heavy construction activities should not occur in an area where MRI procedures are occurring concurrently.

In conclusion

Good space planning practices with consideration to vibration sources, as well as early and meaningful collaboration and consultation between a vibration specialist like HGC Engineering and project architects, structural engineers and planners before, during and after construction, can go a long way to minimizing the impact of vibration on sensitive equipment and by extension patient and staff health and well-being.